34131 Kassel, Germany Telefon: +49 (0)561 - 816 764 93

contact@doks-innovation.com

Automatisieren und skalieren Sie Ihre Intralogistik-Prozesse mit der doks.solution

Wir bieten Ihnen eine drohnen- und sensorgestützte Lösung für die autonome Bestandserfassung und Inventur in verschiedenen Lagertypen im Innen- und Außenbereich, sowie im In- und Outbound.

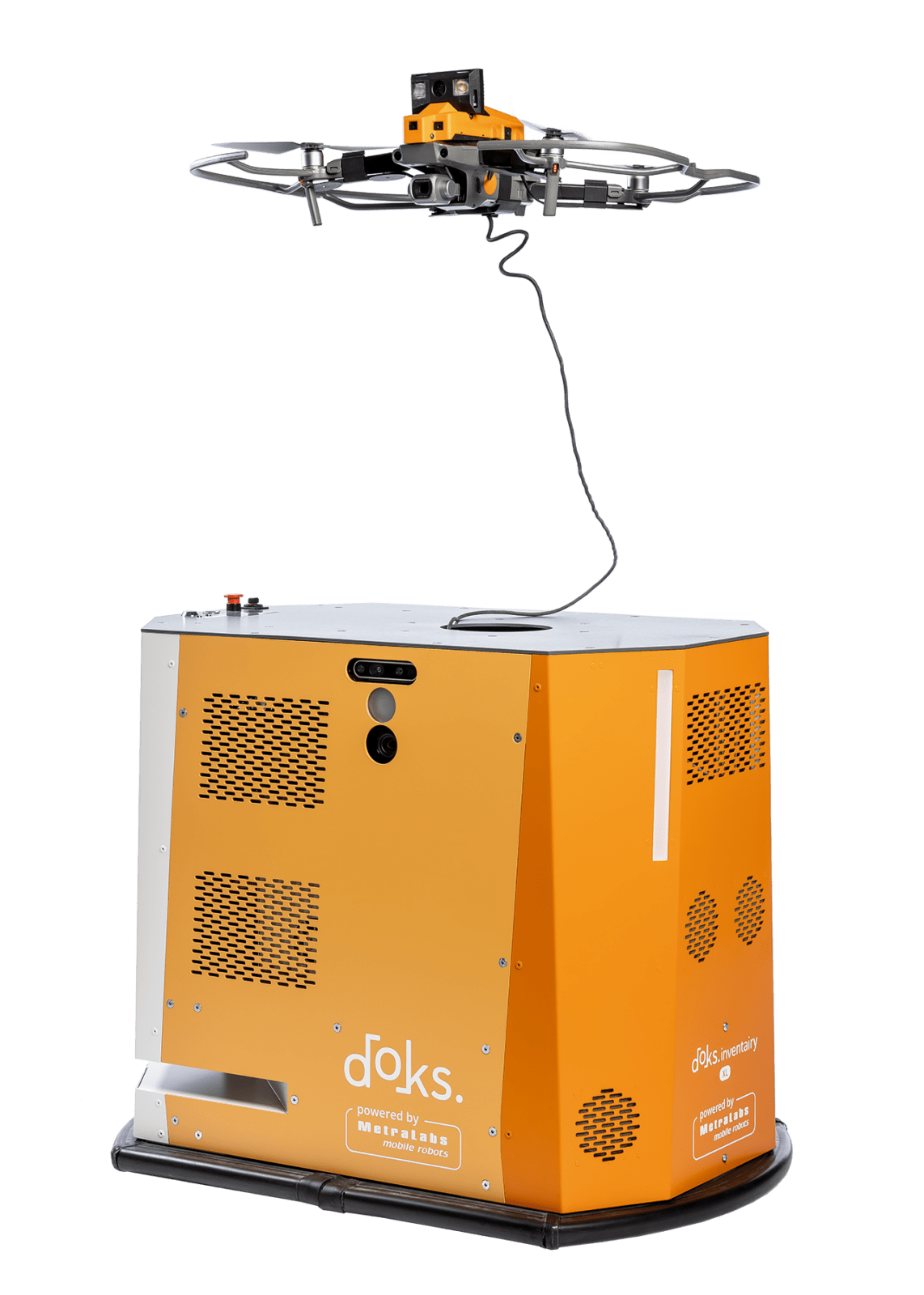

doks.inventairy

Die innovative drohnenbasierte Lösung für die automatisierte Inventur im Hochregallager!

doks.sky

Automatisiertes System für die Bestandsdaten¬erfassung und Inventur in allen Blocklagern im Außenbereich!

doks.gate

Automatisches Scannen und Dokumentieren in der Vorbeifahrt beim Be- und Entladen.

Unser Rover mit Drohne erledigt Ihre Inventur automatisch!

Die innovative drohnenbasierte Lösung für die automatisierte Inventur und Bestandsdaten-Kontrolle in Ihrem Palettenregallager!

#thefutureisnow

Wir machen Lagermanagement unübertroffen einfach!

Gegründet 2017 in Dortmund im Umfeld des Fraunhofer-Instituts für Materialfluss und Logistik IML, beschleunigt doks. innovation mit seinen Lösungen für die Intralogistik die Digitalisierung von Bestandserfassungs- und Inventurprozessen, das Stammdatenmanagements sowie den Transport über kurze Distanzen.

Unsere Kompetenzen & USPs

Sensortechnologie

Maschinelles Lernen

Datenauswertung

Sensorintegration

Autonome Navigation

Logistikverständnis

Wir zeigen Ihnen unsere doks.solution Lösung direkt bei Ihnen im Lager!

Buchen Sie einen Demo-Termin und wir kommen mit unserer Lösung in Ihr Lager! Wir zeigen Ihnen das System und beantworten gerne alle Fragen.

Buchen Sie jetzt einen Demo-Termin bei Ihnen vor Ort!

4-6 Stunden

Bei Ihnen vor Ort